Coefficient of Friction & Wear

Some of da Vinci’s early work in bearing design centered on the shortcomings of existing designs. He began his work with a series of studies exploring the interaction between objects in contact with one another. The experimental equipment da Vinci designed was an innovation in and of itself. Da Vinci studied what factors contributed to friction and correctly concluded that friction is influenced not only by the types of materials in contact, but also the contact area of the two objects. To decrease friction, Leonardo suggested the use of rollers as well as lubricants between sliding surfaces.

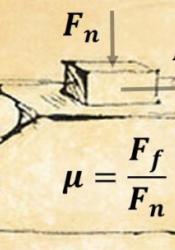

From this work, da Vinci fathered the concept of a “coefficient of friction.” Da Vinci used a value of 0.25 for the coefficient of friction between two “polished” surfaces, which is impressively close to estimates used today (500 years later). This feat is even more impressive due to the mathematical complexity of determining coefficients of friction between nonlubricated surfaces even today.

Alongside friction, da Vinci was also interested in wear (a result of friction). In his day, mechanical objects experienced severe wear and either required frequent maintenance or replacement to maintain functionality. Da Vinci experimentally determined that the direction of wear depended on the load, and was not always vertically downwards, as was previously believed. His experiments also yielded that lubrication alone was insufficient to prevent wear. This led him to investigate the value of rolling elements.

Source: Reti, Ladislao. “LEONARDO ON BEARINGS AND GEARS.” Scientific American, vol. 224, no. 2, 1971, pp. 100–11.

Image: http://www.tribonet.org/wiki/friction-coefficients-in-atmosphere-and-vac...